Improving In-Plant Safety with Fixed, Automated & Moveable Barriers

The right combination of barriers throughout a facility can protect employees.

- By Walt Swietlik

- Apr 01, 2022

Large industrial facilities, expansive warehouses, and massive distribution centers can be dangerous places for employees. Material handling vehicles, machining equipment, and fall hazards in such facilities all present unique safety challenges—especially when labor supply is tight, and shifts may be operating short-handed.

Forklifts, automated guided vehicles (AGVs), pallet jacks, and other materials handling vehicles are necessary to move products in bulk or efficiently from storage to shipping. Yet, these in-plant vehicles can be dangerous for workers on foot inside a plant. Forklifts alone were involved in nearly 7,300 reported accidents in 2020. There were 78 reported deaths due to forklift-related incidents in 2020.

According to OSHA, falls are among the most common causes of serious work-related injuries and deaths. In fact, slips, trips, and falls account for nearly 700 deaths each year. Fall protection continues to be one of OSHA’s Top 10 most frequently cited violations, but machine guarding is routinely part of this annual list, too. More than 1,100 violations were uncovered in 2021.

Many of these incidents could have been prevented with proper training and the right in-plant safety equipment. Specifying the proper barriers for the facility can help mitigate the daily risk employees encounter.

Reducing Floor Accidents with Fixed Barriers

Unlike painted yellow lines, physical barriers can help prevent forklifts from striking pedestrian traffic. Physical barriers are much harder to ignore, and serve additional functions as well. Beyond separating employees from automated processes and dangerous workspaces, barriers may also be used to protect production equipment and/or the building itself from damage by forklifts, AGVs, or other vehicles.

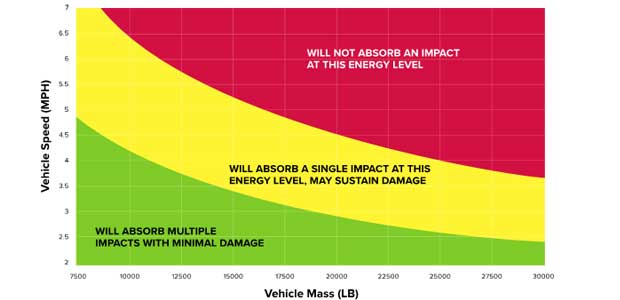

Many manufacturers rate industrial barriers based on their ability to stop an impact of 10,000 pounds at 4 mph—which has been an industry standard for more than 30 years. While this rating provides a meaningful reference for a specific load at a specific speed, it fails to define several key variables:

This article originally appeared in the April 2022 issue of Occupational Health & Safety.