Solution-Dyeing Versus Piece-Dyeing: Does it Make a Difference in PPE?

Understanding the complete fabric creation process can aid in making better PPE choices.

- By Rich Lippert

- Jun 01, 2022

Most of the discourse surrounding personal protective equipment (PPE) is justifiably concentrated on the ability of a garment to minimize exposure to hazards, ultimately making workplaces safer. However, there is one important factor of PPE fabrics that is often overlooked—the dyeing process.

As you weigh your options for PPE workwear, you might be surprised to learn the differences between the “solution-dyeing” process and more traditional dyeing processes known as “piece-dyeing” or “stock-dyeing.”

Visualizing the Difference

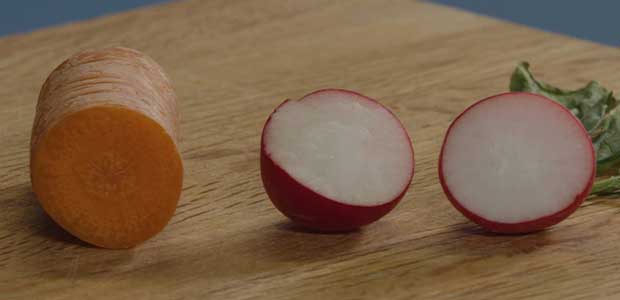

In order to envision the contrast in solution-dyeing and piece-dyeing, consider the difference between a carrot and a radish. When cutting into a carrot, you’ll notice the orange color is consistent throughout the vegetable—top to bottom, in and out. Conversely, slicing into a radish will reveal a white interior color which is very different than its reddish exterior.

This is an excellent analogy for solution-dyeing versus piece-dyeing methods, with the carrot representing solution-dyed fabrics, which has pigmentation added directly to the polymers, and the radish symbolizing piece-dyed fabrics, which is dyed after the fiber has been created.

Technically Speaking

In solution-dyed fabrics, color pigmentation is added to the polymer at the very beginning of the process, rather than after it becomes yarn and woven into fabric. Colorless polymer chips are melted together with color pigments. This melted mass is then extruded through a spinneret, which is a device resembling a showerhead, to create the fiber, and then spun into yarn.

In comparison, piece-dyed fibers are dyed following extrusion, meaning the color only penetrates the outer surface of the material. Both methods have their redeeming qualities, but the question still remains—how do these disparate processes impact PPE and its effectiveness?

Durable Dyes

There are many benefits to utilizing solution-dyed fabrics in PPE garments, most notably the increased durability in the workplace and improved color fastness following industrial laundering. Because the color is built-in to the fiber, solution-dyed PPE retains its color much longer than piece-dyed fabrics. The prolonged lifetime of these products underscores the fact that solution-dyeing maximizes an organization’s PPE dollars.

This article originally appeared in the June 2022 issue of Occupational Health & Safety.